|

| |

Haunchers - Notchers

|

These heavy duty machines are

used to make shaped cuts in the end or along the edge of a board or

panel. Typical uses include box-joint, finger-joint or tenon cuts,

shaping the edges of square ballisters or dentil moulding, notching the

edge of the panel, or shaping the end of the moulding such as a window

aprons, etc.

|

|

CHA-8: Hauncher - Notcher Machine

Details

- Cuts the profile in the end or

along the edge of a board or panel

- Table moves up-down against

horizontal spindle

- Air / Oil feed system

- Air clamps

- Climb cut and table insert

ensure the clean cut even in cross grain cut

- Air-Oil adjustable feed system

- Automatic cycle

- Max. working height - 5"

- Max. cutting depth - 2"

- Tool clamping width - 8"

- Cutter: diameter - 8"

- Motor - 10 HP

CHB-8: Hauncher - Notcher Machine Details

- Horizontal spindle moves

up-down pass the material clamped to the table

- Climb cut and table insert

ensure the clean cut even in cross grain cut

- Air-Oil adjustable feed system

- Air clamps

- Automatic cycle

- Max. work piece height - 4"

- Max. Cutting depth - 2 "

- Max. cutting width – 8”

- Cutter diameter - 8"

- Motor – 7.5HP, 10HP

- Can be synchronized with

TigerStop like systems

CHB-12, CHB-16, CHB-20 Hauncher Notcher Machine

Details

- Horizontal spindle moves

up-down against the material clamped to the table

- Climb cut and table insert

ensure the clean cut even in cross grain cut

- Air-Oil adjustable feed system

- Air clamps

- Automatic cycle

- Max. work piece height - 8"

- Max. Cutting depth - 2 ½"

- Max. cutting width - 12", 16",

20"

- Cutter diameter - 10"

- Motor - 15HP, 20HP, 25HP

CHF-8: Beaded Frame Notcher

The CHF-8

Hauncher is designed for machining of beaded face frames, cabinet doors, etc..

Machine table with the clamped workpiece moves hydraulically down pass the

horizontal spindle with profile cutter. The CHF-8 cuts

all required corners and notches in seconds without the need to change a

set-up. The Air-Oil feed system, climb cut motion and table insert ensure the

clean cut even across the grain of the wood.

- Max. Cutting Depth: 1”

- Max. Cutting Height: 2”

- Max. Tool length: 8”

- Cutter Diameter: 6”

- Spindle Diameter: 1.5” or40mm

- Motor HP: 7.5

- Nbr. of clamps: 4

- Nbr. of flip-stops: 4

- Stop bar length: 36”

- Electric: 230/460V

- Weight : 600 lbs

|

View CHF-8 Detail Photos

|

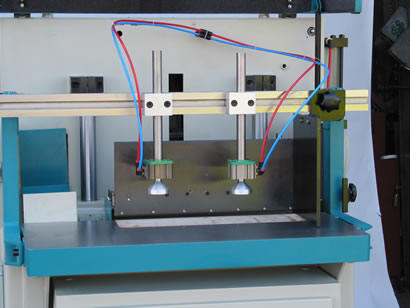

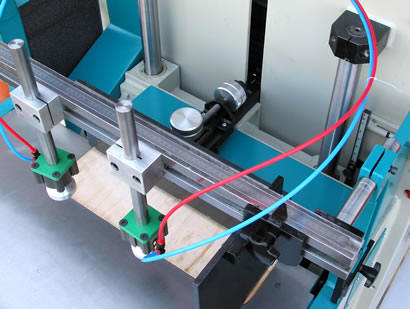

Double Spindle

Hauncher - Notcher Machine Details

- Machine fully designed as per

customer specifications and needs

Also available - Special Haunchers - Notchers

- Special hauncher for bed frames

- Sill cover notcher

- Special hauncher for ammunition

boxes

- Toe-kick notcher for mass

production

- Special window hauncher

|